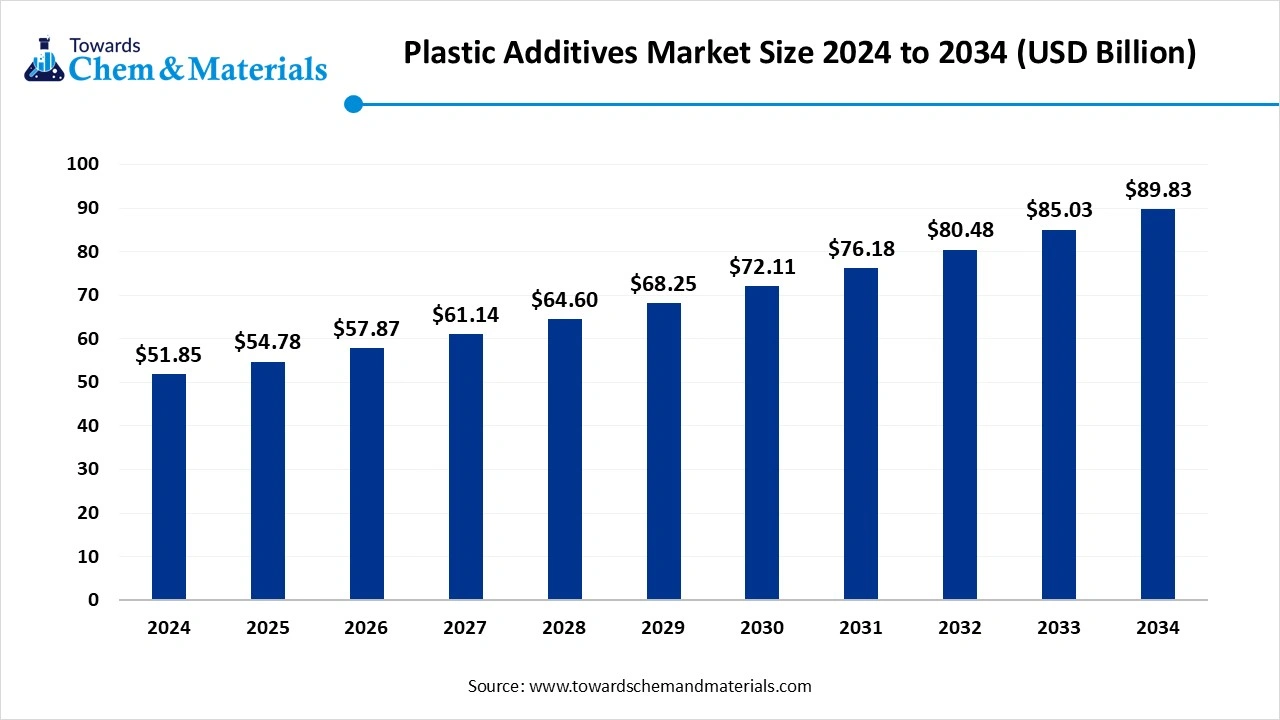

Plastic Additives Market Size to Surpass USD 89.83 Billion by 2034

According to Towards Chemical and Materials, the global plastic additives market size was estimated at USD 51.85 billion in 2024 and is expected to surpass around USD 89.83 billion by 2034, growing at a compound annual growth rate (CAGR) of 5.65% over the forecast period from 2025 to 2034.

Ottawa, Aug. 28, 2025 (GLOBE NEWSWIRE) -- The global plastic additives market size is valued at USD 54.78 billion in 2025 and is anticipated to reach around USD 89.83 billion by 2034, growing at a compound annual growth rate (CAGR) of 5.65% over the forecast period from 2025 to 2034. The Asia Pacific plastic additives market dominated with a revenue share of 60% in 2023. A study published by Towards Chemical and Materials a sister firm of Precedence Research.

The market is growing with increasing demand from package, automotive, and construction applications, and rapid urbanization and eco-friendly innovations, pointing to a resilient growth trajectory that focuses on sustainability.

Download a Sample Report Here @ https://www.towardschemandmaterials.com/download-sample/5682

Plastic Additives Market Overview

Plastic additives are the chemical substances incorporated into plastic materials to improve their properties and performance such as stabilizers, plasticizers, flame retardants, and colorants. The additives improve durability, flexibility, UV (Ultraviolet) resistance and efficiency of processing so that plastics can be molded, extruded or cast to meet the functionality of end use applications.

The market is driven by the demand from key industries such as automotive, packaging, construction, and electronics that are looking for high performance and customized material performance. There is a greater trend of thinking about lightweight, high strength plastic, along with the regulatory environment requiring reduction of potentially dangerous additives. The region of Asia Pacific is leading the market in production and consumption because of increased industrialization, while North America and Europe are focusing on sustainable additives and bio-based additives.

Plastic Additives Market Report Scope

| Report Attribute | Details |

| Market size value in 2025 | USD 54.78billion |

| Revenue forecast in 2034 | USD 89.83 billion |

| Growth rate | CAGR of 5.65% from 2024 to 2034 |

| Base year for estimation | 2024 |

| Historical data | 2021 - 2024 |

| Forecast period | 2025 - 2034 |

| Segments covered | By Additive Type, By Additive Type, By Function , By End-Use, By Regional |

| Regional scope | North America; Europe; Asia Pacific; Latin America; MEA |

| Country scope | U.S.; Canada; Mexico; Germany; UK; Germany; France; Italy; Spain; Russia; Denmark; Sweden; Norway; China; India; Japan; Australia; South Korea; Indonesia; Vietnam; Brazil; Argentina; South Africa; Saudi Arabia; UAE; Kuwait |

| Key companies profiled | BASF SE; Clariant AG; Albemarle Corporation; Songwon Industrial Co., Ltd.; Nouryon; LANXESS AG; Evonik Industries AG; Kaneka Corporation; The Dow Chemical Company; ExxonMobil Corporation |

Buy Now this Premium Research Report at a Special Price Against the List Price With [Express Delivery] @ https://www.towardschemandmaterials.com/price/5682

BASF Plastic Additives:

The key component for your sustainable plastics solutions

Welcome our Product Carbon Footprint services to the VALERAS™ portfolio of sustainable solutions and services

Plastics, with unique properties such as versatility, durability, and light-weighting, are about to be transformed through creative additive platforms that will deliver valuable, sustainable solutions, and enhance savings in terms of cost and resources.

The plastics industry has a strong mandate to increase sustainability, reduce waste, and enable circularity. As a leading global producer of plastic additives, BASF takes this goal very seriously. The product carbon footprint service is our latest addition to VALERAS portfolio and covers cradle-to-gate phase.

With VALERAS™, the Plastic Additives business has utilized its unparalleled experience in stabilization, protection, technical, sustainability and regulatory support to strengthen BASF’s two technology approaches to the circular economy: “Extend the loop” and “Close the loop”. These solutions offer resource-efficient products and services which support our customers’ circularity journeys.

What are the Major Trends in the Plastic Additives Market?

- Recycling and Reuse Innovations- Additives that significantly improve the recyclability of plastics are becoming increasingly common, resulting in addressing world waste problems while aligning with circular economy initiatives throughout making old plastic usable again.

- Light Weight Material Demand- The ever-increasing convenience of lighter plastics has never been easier as the lighter material characteristics gained through the additive directly affects multiple industries. Industries such as automotive and aerospace have continually driven lighter plastics that are produced with additives to enhance their performance while also contributing to energy efficiency and ultimately reduce emissions in transport.

- Regulatory Compliance and Safety Standards- Increasing regulations and safety standards require manufacturers to utilize additives that mitigate compliance, product safety and quality from many applications including food packaging, medical devices etc.

Growth Factor in the Plastic Additives Market

Growth Factor

Is the Growth in Demand for Plastic Additives Industry-Wide Plastic Adoption?

One significant driver for growth in the plastic additives market is the increase in plastics usage overall across multiple segments and sectors, including packaging, automotive, electronics, construction, and consumer goods. Packaging is a massive consumer of plastics—and because it accounts for so much of the waste produced, it is an equally large producer of plastic waste and plastic waste, accounting for about 40% of the worlds' plastic waste. In the U.S. packaging accounts for 37% of total plastic waste. In Europe it's 38% and in China it's 45%.

Together, these areas account for approximately 60% of global packaging waste. Because of the extreme consumption, there will be an increase in additive use to improve durability, flexibility and safety of plastics. In addition, the automotive industry's push to incorporate lightweight plastic components to improve their fleet's fuel efficiency, additive adoption rates are expected to continue to rise.

Market Opportunity

Is Increased Demand for Customisation and High-Performance Plastics Fueling Additive Innovation?

The biggest opportunity for plastic additives is the role they can play in the growing demand for customisation and solutions that enhance performance, durability, safety, and sustainability. In March of 2025, SI Group unveiled its latest polymer additive innovations at Chinaplas 2025. Innovations included EVERCYCLE™ to promote performance, WESTON™ 705 antioxidants to improve stability and ANOX™ NDB™ S2226P low-emission solutions to provide safer processing. SI Group's Non-Dust Blends™ technology also promotes a cleaner, more efficient method of manufacturing.

These innovations cater to a wide range of industries including automotive, electronics, packaging, etc., where custom additive solutions meet performance criteria, improve recyclability, and support eco-friendly manufacturing. There is a significant global push for sustainable material innovations.

Limitations and Challenges in the Plastic Additives Market

- Environmental Concern- Some plastic additives, particularly phthalates and flame retardants, can contribute to environmental pollution and health risk. With the continued introduction of bans and regulations on harmful additives, there is increased pressure on manufacturers to create safe, sustainable alternatives.

- Prices of Petrochemicals- Plastic additives are mostly derived from petrochemical-produced raw materials. Price changes with crude oil and disruption of supply chains can adversely affect production costs and therefore affect profit and pricing stability in the long term.

- Growing Demand for Alternatives- The move towards biodegradable and bio-based plastics is reducing the need for conventional additives. As sustainability movements emerge in the marketplace, this will further challenge the traditional additives makers to adapt through innovation, or risk losing market share.

For more information, visit the Towards Chemical and Materials website or email the team at sales@towardschemandmaterials.com| +1 804 441 9344

Why Did Asia Pacific Dominate the Plastic Additives Market In 2024?

The Asia Pacific plastic additives market size accounted for USD 32.87 billion in 2025 and is forecasted to hit around USD 58.39 billion by 2034, representing a CAGR of 6.50% from 2025 to 2034.

Asia Pacific dominates the plastic additives market in 2024. Asia Pacific region leads the industry through deep resin capability, dense converter networks in packaging, electronics, automotive, and construction, and numerous end-use hubs. Local manufacturers offer a variety of additive portfolios -- antioxidants, UV/HALS, flame retardants, plasticizers, and nucleating and impact modifiers -- while also wanting regulators to enable increased use of safer chemistries, as well as recycled contents for compatibility. Demand remains broad and steady with rapid growth in e-commerce packaging, and planned infrastructure projects. Strong tooling capabilities in China, Japan, South Korea, and India mean shorter development cycles; recent chemical recycling pilot projects favour compatibilizers and stabilizers designed for higher-recycled blends.

China--The regional benchmark

China anchors scale and speed expansive PP/PE/PVC processing, fast-moving EV and appliance output, and improving packaging. The upstream citric acid capability provides cost-effective supply of antioxidants and stabilizers. And product safety and recyclability standards will drive stronger uptake of materials for patterns that require non-phthalate plasticizers, low-VOC additives, and UV/flame packages for building materials.

-

In December 2024, Clariant is expanding its production site in Cangzhou for manufacturing its multifunctional Nylostab™ S-EED™ additive to improve the product quality of nylon products, improving colour stability, heat resistance, and composite compatibility, while boosting productivity. Also, in Partnership with Beijing Tiangang Auxiliary Co., Ltd., Clariant commenced a new second high-performance additives production line in Hebei Province of China.

Why Is Middle East And Africa The Fastest Growing Region In The Plastic Additives Market?

Middle East and Africa expects the fastest growth in the market during the forecast period. MEA is the fastest-growing region, with resin-rich economies investing downstream conversion efforts in integrated parks for films, pipes, cables, and packaging. Further resin conversion is expected via new PP/PE capacities, infrastructure spend, and warm, high-UV climates increasing the profile for stabilizer systems and flame-retardant solutions. The programs for localization and export corridors to Europe and Asia are being realized, and there has been a further uplift of specialty additive uptake in more railways and water/agri—increasing demand for oxidants, UV/HALS, and slip/antiblock packages for irrigation, geo-membranes, and agricultural films.

Saudi Arabia Market Trend

Saudi Arabia is taking advantage of plentiful petrochemical raw materials to develop its specialty chemicals and plastics industries. Increased infrastructure projects, more stringent building codes, and improved food-contact regulations have propelled the use of more sophisticated stabilizers, non-halogen flame retardants, and recyclate-compliant additives. Sustainability targets are also increasing the use of more environmentally friendly formulations to improve local production quality and become more competitive on the global export market.

Plastic Additives Market Segmentation

Additive Type Insights

Why is Plasticizers Segment Dominated the Plastic Additives Market in 2024?

The plasticizers segment dominated the market in 2024. Plasticizers are principally responsible for upgrading and reinforcing the flexibility, durability, and workability of plastics for a variety of uses. Market demand in packaging, construction, and consumer goods has propelled plasticizers to command a strong presence in the market. In addition, plasticizers are not only widely used across a variety of industries, but also offer compatibility with many polymers. Thus, manufacturers seeking a cost-effective means of maximizing performance in flexibility, durability and workability have preferred plasticizers often, especially for polyvinyl chloride (PVC).

Antimicrobial additives segment projected to grow at the fastest rate during the projected period, driven by growth in awareness around hygiene, safety of products, and longer shelf life. New technology that offers long-lasting antimicrobial protection in addition to compliance around safer and cleaner materials will enhance upstream adoption throughout the supply chain by actors in the plastic industry, especially in sectors already focused on health and wellness, and product legitimacy, i.e., food and beverage.

Polymer Type Insights

Why does the Polyvinyl Chloride Segment Dominate the Plastic Additives Market?

Polyvinyl Chloride segment held the largest share of the market in 2024, driven by its wide range of applications in construction, automotive, packaging, and electrical. Due to its versatility, durability, and relatively low cost, PVC is a preferred material by many end-use industries. In combination with additives, PVC's flexibility, resistance to adverse conditions, and longevity are improved, and it is king in the production of rigid, and flexible products including pipes, cables, profiles, and films.

The bioplastics segment expected to grow at the fastest rate during the forecast period, aided by the global shift toward sustainable, eco-friendly materials. There is an increasing global regulatory push to reduce plastic waste, and there is more consumer interest in biodegradable and compostable products. Additives are critical in bioplastics to improve the performance, processability, and longevity of both bioplastics and their resultant products, while enabling a broader range to be made in packaging, agriculture, and consumer goods.

Function Insights

Which Function Held the Largest Share in the Plastic Additives Market in 2024?

Durability segment held the dominating share in market in 2024, primarily due to the need for improving the toughness, weather ability, and life expectancy of plastic products across a range of products. Durability additives can improve performance against wear, UV exposure, and chemical degradation and are used pervasively in construction materials, automotive applications, and outdoor products. Their role in ensuring product performance and reliability and in avoiding replacement costs has resulted in strong demand across industrial and consumer applications.

The aesthetic improvement segment is expected to grow at the highest CAGR throughout the forecast period due to growing consumer preferences toward visually appealing and customized plastic products. The heightened demand stems also from growing trends in premium product design and brand differentiation - particularly in markets where visual attributes heavily weigh on purchasing decisions.

End-Use Industry Insights

Which End-Use Industry Dominated the Plastic Additives Market in 2024?

The packaging segment dominated the market in 2024, with the sector consuming and using plastics for food, beverages, personal care, and industrial products. Additives improve package performance by enhancing barrier properties, flexibility, durability, and aesthetics while allowing for lightweight designs. The increasing demand for convenient, safe, and aesthetically pleasing packaged products has bolstered the segment's leading position in the market.

The healthcare segment is predicted to grow the fastest during the forecast period, primarily due to the increasing utilization of plastics, and advanced plastics, in medical devices, diagnostic equipment, and pharmaceutical packaging. Additives strengthen the safety, antimicrobial functions, and durability of healthcare products to comply with strict regulations and performance requirements. The growing demand for health care investments, disposable medical supplies, and biocompatibility materials are the key elements driving the healthcare segment's rapid growth.

More Insights in Towards Chemical and Materials:

- Performance Additives Market : https://www.towardschemandmaterials.com/insights/performance-additives-market

- Specialty Fuel Additives Market : https://www.towardschemandmaterials.com/insights/specialty-fuel-additives-market

- Lubricant Additives Market : https://www.towardschemandmaterials.com/insights/lubricant-additives-market

- Antimicrobial Additives Market : https://www.towardschemandmaterials.com/insights/antimicrobial-additives-market

- Recycled Plastics Market : https://www.towardschemandmaterials.com/insights/recycled-plastic-market

- Sustainable Plastics Market : https://www.towardschemandmaterials.com/insights/sustainable-plastics-market

- U.S. Plastic Compounding Market : https://www.towardschemandmaterials.com/insights/us-plastic-compounding-market

- Circular Plastics Market : https://www.towardschemandmaterials.com/insights/circular-plastics-market

- U.S. Transparent Plastics Market : https://www.towardschemandmaterials.com/insights/us-transparent-plastics-market

- Recycled Plastics In Green Building Materials Market : https://www.towardschemandmaterials.com/insights/recycled-plastics-in-green-building-materials-market

- Transparent Plastics Market : https://www.towardschemandmaterials.com/insights/transparent-plastics-market

- Europe Bioplastics Market : https://www.towardschemandmaterials.com/insights/europe-bioplastic-market

- Asia Pacific Plastic Additives Market : https://www.towardschemandmaterials.com/insights/asia-pacific-plastic-additives-market

- Plastics Extruded Market : https://www.towardschemandmaterials.com/insights/plastics-extruded-market

- Plasticizers Market : https://www.towardschemandmaterials.com/insights/plasticizers-market

- Asia Pacific Bioplastics Market ; https://www.towardschemandmaterials.com/insights/asia-pacific-bioplastics-market

- Bioplastics Market ; https://www.towardschemandmaterials.com/insights/bioplastics-market

- Thermoplastic Elastomers (TPEs) Market : https://www.towardschemandmaterials.com/insights/thermoplastic-elastomers-market

- Engineering Plastics Market : https://www.towardschemandmaterials.com/insights/engineering-plastics-market

- Europe Plastics Market : https://www.towardschemandmaterials.com/insights/europe-plastics-market

- Recycled Thermoplastics Market : https://www.towardschemandmaterials.com/insights/recycled-thermoplastics-market

- Biopharma Plastic Market : https://www.towardschemandmaterials.com/insights/biopharma-plastic-market

- Plastic Antioxidants Market : https://www.towardschemandmaterials.com/insights/plastic-antioxidants-market

- Europe Blow Molded Plastic Market ; https://www.towardschemandmaterials.com/insights/europe-blow-molded-plastic-market

- Biobased Biodegradable Plastic Market : https://www.towardschemandmaterials.com/insights/biobased-biodegradable-plastic-market

- High Performance Plastics Market : https://www.towardschemandmaterials.com/insights/high-performance-plastics-market

Plastic Additives Market Top Key Companies:

- Adeka Corporation

- Albemarle Corporation

- Arkema S.A.

- BASF SE

- Baerlocher GmbH

- Clariant AG

- Dow Inc.

- Dupont de Nemours, Inc.

- Evonik Industries AG

- ExxonMobil Chemical

- INEOS Group

- Kaneka Corporation

- Lanxess AG

- LG Chem Ltd.

- Milliken & Company

- Mitsui Chemicals, Inc.

- SABIC

- Solvay S.A.

- Songwon Industrial Co., Ltd.

- Shandong Rike Chemical Co., Ltd

Recent Developments

- In March 2025, Venator, a producer of pigments and additives based in the UK, announced it has implemented an automated tool to calculate the carbon footprint of its products. Functional additives such as UV stabilizers, heat stabilizers, antioxidants, and flame retardants boost durability and security.

- In September 2023, BASF has launched the first biomass-balance plastic additives in the industry-Irganox® 1010 BMBcert™ and Irganox® 1076 FD BMBcert™.

Plastic Additives Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2021 to 2034. For this study, Towards Chemical and Materials has segmented the global Plastic Additives Market

By Additive Type

- Plasticizers (e.g., phthalates, adipates, trimellitates)

- Stabilizers

- Heat Stabilizers

- UV Stabilizers

- Antioxidants

- Flame Retardants

- Impact Modifiers

- Antimicrobial Additives

- Colorants / Pigments

- Lubricants

- Blowing Agents

- Antistatic Agents

- Nucleating & Clarifying Agents

- Foaming Agents

- Processing Aids

- Anti-blocking Agents

- Slip Agents

- Light Diffusers

- Anti-fogging Agents

By Polymer Type

- Polyethylene (PE)

- LDPE

- HDPE

- LLDPE

- Polypropylene (PP)

- Polyvinyl Chloride (PVC)

- Polystyrene (PS)

- Polyethylene Terephthalate (PET)

- Acrylonitrile Butadiene Styrene (ABS)

- Polycarbonate (PC)

- Polyamide (Nylon)

- Polyurethane (PU)

- Engineering Plastics

- Bioplastics / Biodegradable Polymers

By Function

- Property Enhancement

- Thermal, Electrical, Mechanical Strength

- Process Aid

- Flow modifiers, mold release

- Aesthetic Improvement

- Color, surface finish

- Durability/Protection

- UV, oxidation, microbial

- Safety/Compliance

- Flame retardancy, food contact regulations

By End-Use Industry

- Packaging

- Rigid Packaging

- Flexible Packaging

- Automotive & Transportation

- Building & Construction

- Consumer Goods

- Electronics

- Household items

- Electrical & Electronics

- Textiles & Fibers

- Healthcare / Medical Devices

- Agriculture

- Greenhouse Films, Mulch Films

- Industrial Applications

By Regional

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East Africa

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/price/5682

About Us

Towards Chemical and Materials is a leading global consulting firm specializing in providing comprehensive and strategic research solutions across the chemical and materials industries. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations.

Our Trusted Data Partners

Precedence Research | Statifacts | Towards Packaging | Towards Healthcare | Towards Food and Beverages | Towards Chemical and Materials | Towards Consumer Goods | Nova One Advisor |

For Latest Update Follow Us: https://www.linkedin.com/company/towards-chem-and-materials/

USA: +1 804 441 9344

APAC: +61 485 981 310 or +91 87933 22019

Europe: +44 7383 092 044

Email: sales@towardschemandmaterials.com

Web: https://www.towardschemandmaterials.com/

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.